|

Specification

1000PSI/PN63

Reduced full bore

Lost wax precision casting

Blow-out proof stem

Sanitary Design

PED97/23/EC(CE0035) APPROVED

Thread: ASME B 1.20.1 BS21. DIN2999/259.

ISO228-1, JIS B 0203, ISO7/1

Inspection and testing: DIN3230/3, EN12266

|

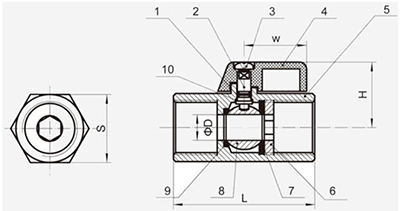

SIZE

|

1/4″

|

3/8″

|

1/2″

|

3/4″

|

1″

|

|

D

|

7

|

7

|

9.2

|

12.5

|

15

|

|

L

|

42

|

42

|

46

|

54

|

65

|

|

H

|

26.5

|

26.5

|

28.3

|

31.5

|

34

|

|

W

|

22.8

|

22.8

|

22.8

|

22.8

|

22.8

|

Features

Material List

|

ITEM

|

DESIGNATION

|

Material

|

|

1

|

O-RING

|

VITON

|

|

2

|

STEM

|

304

|

|

3

|

BOLT

|

304

|

|

4

|

LEVER

|

ALUMINUM ALLOY

|

|

5

|

BODY

|

CF8M

|

|

6

|

CAP

|

CF8M

|

|

7

|

BALL SEAT(A)

|

R-PTFE

|

|

8

|

Ball

|

CF8M

|

|

9

|

BALL SEAT(B)

|

RPTFE

|

|

10

|

THRUST WASHER

|

PTFE

|

APPLICATION

Reduce port, thread connectors design, investment casting, blow-out proof stem, mainly used as the medium for the truncated or connection line, compact structure,reliable sealing, simple structure, easy to maintenance, affordable, fully opening or closing, the sealing surface and the dielectric isolation of the ball and seat, through the media, will not cause valve sealing surface erosion, easy operation and maintenance.

- Nominal Pressure: 1000PSI/PN63

- Temperature Range: -29℃>120℃ (based on the different temperatures between body materials and sealing surface materials)

- Medium: Using different materials can be applied to water, oil, gas or caustic liquid.

- Thread Type: G, NPT, PT, Rp, Rc, DIN 259/2999.

- PED97/23/EC Approved

- Casting Approved AD2000-W0

- Inspection Testing: API598, EN12266

|